Categories

New products

-

Lens Ring Joint Gasket

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading Lens Ring Joint Gasket manufacturers in China, welcome to wholesale low price Lens Ring Joint Gasket from our factory

-

Double Jacket Gasket

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading Double Jacket Gasket manufacturers in China, welcome to wholesale low price Double Jacket Gasket from our factory

-

Corrugated Gaskets

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading Corrugated Gaskets manufacturers in China, welcome to wholesale low price Corrugated Gaskets from our factory

-

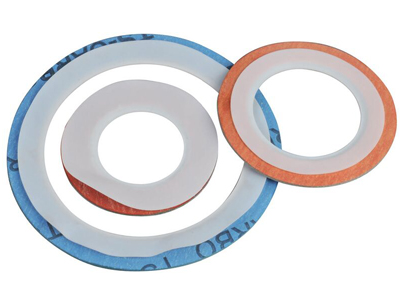

PTFE Envelope Gasket

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading PTFE Envelope Gasket manufacturers in China, welcome to wholesale low price PTFE Envelope Gasket from our factory

-

Rubber Sheet

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading Rubber Sheet manufacturers in China, welcome to wholesale low price Rubber Sheet from our factory

Graphite Packing Reinforced with Metal Wire

Graphite packing reinforced with wire is braided from expanded graphite yarns, reinforced with metal wire, normally reinforced with inconel wire. It retains all the inherent benefits of Kaxite P400 flexible graphite packing. The wire reinforcement provides greater mechanical strength, used for high pressure and temperatures.

Kaxite P401EK

Corrosion inhibitor acts as a sacrificial anode to protect the valve stem and the stuffing box.

Typical Application

> Flexible graphite packing is a multi-service packing capable of a wide variety of uses throughout a plant.

> It can be used in valves, pumps, expansion joints, mixers and agitators in high-pressure and temperature.

> Excellent for use in steam turbines, high temperature motor-actuated valves

> High temperature and high pressure valve applications in general.

Prime Features

> It can be reinforced with nickel, stainless steel, copper, etc.

> High pressure, high temperature

> Wide variety of uses throughout a plant

> Precaution: in oxidizing environment may use with Kaxite 4**R anti-extrusion packing rings.

Technical Data

| Material | 100% Expanded Graphite Yarn and Metal Wire | |

| Temperature Range |

-200 up to +555 -200 up to +650 |

|

| Process | Rotating | 5 Mpa |

| Reciprocating | 15 Mpa | |

| Valves | 30 Mpa | |

| Shaft Speed | 23m/s in rotary | |

| PH | 0~14 | |

| Density | 1.5 g/cm3 | |